The Royal Navy made many important inventions relating to mines during the 19th century, but took little serious interest in producing them prior to World War I. Notable was Sir Charles Pasley who in 1839 destroyed the wreck of the Royal George using an underwater charge fired by a remotely controlled electric current, probably the first underwater explosion triggered by electricity. By 1870, the Royal Navy had developed a controlled mine system to be used as a defense for a temporary base. Two types were chosen, one to fired directly from shore and the other to be fired by an inertial trigger with power again supplied by the shore base. Only a few of these were manufactured.

By the mid-1870s, experimental work at HMS Vernon, the Torpedo School at Portsmouth, had developed what was called an "electromechanical" mine which used a mechanical or inertia type contact maker, with power supplied from a battery within the mine case. This was apparently the first mine that had an electric battery within the mine itself.

Another important invention developed at HMS Vernon was the automatic depth-fixing anchor. All previous moored mines used a fixed-length anchor cable which had to be cut according to the depth desired. The automatic anchor allowed the mine to be placed at the desired depth by simply adjusting the mechanism.

Although both inventions had obvious advantages, neither was adopted by the Royal Navy for either their own mines or in mines procured from other nations.

By 1894, the Admiralty decided to abandon mining with the exception of a few of the 1873 type kept for experimental and training purposes. In 1900 the Commander-in-Chief of the Mediterranean specifically requested an automatic mine design and some low-priority work was undertaken at HMS Vernon, but in 1903 the design was abandoned.

The Russo-Japanese War renewed interest in mines again and in 1906 the "Navy Spherical Mine" was developed (see below). This was the standard mine at the start of World War I, when it was found to be unreliable.

Until after the end of World War II most British mines had both a "type" letter and a Mark number. Between about 1918 and 1930 horned contact mines were designated as either "Type H" for those mines using Hertz (acid) horns or "Type T" for Trigger (switch) mines. Moored mines designed after the early 1920s generally had only Mark numbers, but this was not always the case. From that period onwards until after the end of World War II there were the following designations in general use:

- Mark numbers only

Moored contact, snagline, acoustic and antenna mines

- A Mark Y

Air launched mines

- M Mark Y

Special magnetic ground mines

- S Mark Y

Submarine launched ground mines

Where "Y" represents the various mark numbers.

In addition, there were also "R" mines, intended for use in rivers, "L" mines that were shore controlled and an "O" mine that oscillated from bottom to surface. These were all apparently scrapped shortly after the war ended. Sometime in the 1950s these designations were merged into a single Mark series. Unfortunately, Mark numbers were then reused, causing some confusion.

Contact mines with Hertz Horns were common in designs from World War I to about 1922. Each horn contained acid. Contact with the horn broke open the acid container which energized a battery and exploded the mine. British contact mines were considered unreliable until a German one was captured and duplicated. In the 1920s a variation was developed that replaced the acid horns with switch triggers that activated when a ship hit a horn. By definition, horned mines were short ranged weapons and fields needed to be densely packed in order to be effective against shipping.

Late in World War I the British developed a magnetic trigger for ground mines. This was not very successful and little post-war work was done in this area for over a decade. Not until 1936 was a new development order placed for a magnetic trigger for moored mines. A small production order was placed in July 1939 with some 200 being delivered by April 1940. These used a coil-rod (CR) which was fired by an increase in the rate of change of magnetism in the horizontal portion of the field around the trigger. Various delay mechanism were employed to ensure that the ship was close to the mine before firing, not always successfully.

Antenna mines using underwater electric potential (UEP) were developed during World War II, apparently with USA help.

An acoustic trigger was developed with USA help in the summer of 1942 and first used that fall. Combined acoustic/magnetic triggers were developed the following year and first employed in April 1943. A magnetic/pressure trigger was developed late in the war but it did not see service.

British Aerospace developed a microprocessor sensor and processing unit (SAP) in the 1980s that used magnetic and pressure sensors as inputs. This design analyzes acoustic frequencies in three bands intended to cover sonar, engines and propeller noises so as to provide a high degree of target identification. The mines can thus be programmed prior to launch to fire for specific kinds of targets.

Owing to shortages of TNT and RDX (cyclonite) most World War II mines had had 50/50 ammonium nitrate and TNT (amatol) warheads. This was a low quality explosive but was later improved by the addition of about 20% aluminum to produce minol. During the modernization program of the 1980s it was discovered that many of the TNT and RDX fillings of the World War II-era mines had crystallized, causing at least two mines to explode prematurely.

At the beginning of the "Great War" the British had about 4,000 of their unreliable "Navy Spherical Mine" on hand and had tried out a few other types developed by other nations. Sometime soon after the start of the war, the British procured 7,500 Russian mines left at Port Arthur at the end of the Russo-Japanese War.

Britain attempted a variety of mine and physical barriers across the Dover Straits, the North Channel and the Adriatic Sea with a total of 128,000 mines being laid. Most of these fields were of relatively limited value, with the exception of the Irish Sea Barrage, which sank 10 U-boats. Minefields laid in enemy waters were more effective. British mines sank a total of 150 enemy war vessels and naval auxiliaries including some 35 U-boats. Worldwide, British mines are reckoned to have sunk a total of 1,047 enemy vessels and damaged a further 541. A total of 48 German submarines were sunk by all Allied mines in World War I.

British contact mines of this era suffered from a variety of faults, especially when compared to the German equivalents and to the USA "K" type mines. As noted above, a magnetic ground mine was developed and deployed in August of 1918, but this was too late to be of significant use and was not very successful. Captain Taprell Dorling, commander of a destroyer minelayer during World War I, states in his book "Swept Channels" that in 1917 the Royal Navy had 20,000 mines in stock but "only 1,500 were fit for laying."

During World War II the RAF Home Command laid 48,158 mines during the entire war in enemy waters and these sank 545 merchant ships of 591,143 tons gross and 217 assorted warships of 147,264 tons displacement. Over 20,000 additional mines were laid by surface ships and submarines. The success of these additional mines is not broken out, but "Naval Weapons of World War Two" claims that British mines in total sank 1,050 Axis warships and merchant ships and damaged a further 540.

As opposed to the successes achieved via offensive mining, it appears that the British greatly overrated the effectiveness of mines as defensive weapons during World War II. Some 170,000 mines were laid in protective fields by surface ships, the majority in the Iceland and Faeroes passages. This massive effort resulted in exactly one U-boat (U-647) being sunk and had no appreciable effect on the number of U-boats engaged in anti-commerce operations. This might have been forecasted by a study of the 1918 Orkney to Norway mine barrier (also known as the North Sea Mine Barrage) which was an expensive failure. In some ways, these defensive fields restricted the Royal Navy more than the Kriegsmarine. For example, although the German small battleships Gneisenau and Scharnhorst were able to traverse the Dover Straits in 1942, the first British capital ship to do so was HMS Warspite, which passed that way only after the Normandy invasion in June 1944.

An early World War I mine apparently designed by Sir Hiram Maxim, of machine gun fame. No details are available.

See the Furness Railway Steam Mine at The Vickers Photographic Archive.

A moored mine using an automatic anchor and an arm-operated firing mechanism. Total weight of 900 lbs. (408 kg), charge was 250 lbs. (113 kg) gun cotton and diameter of 38 in (96.5 cm). Production started in late 1906 with about 1,000 on hand by 1907 but only 4,000 available by the start of World War I.

Similar to the Mark I and II but with a slightly smaller charge of 245 lbs. (111 kg) gun cotton.

Invented by Captain G. Elia of the Italian Navy, this bouyant mine used a long lever. When struck by a ship, the lever rotated and detonated the mine. Mark IV total weight of 448 lbs. (203 kg), charge of 220 lbs. (100 kg) TNT and diameter of 32.9 in (83.6 cm). Mark V total weight of 440 lbs. (200 kg), charge of 220 lbs. (100 kg) TNT and diameter of 32.9 in (83.6 cm). Mark VI total weight of 306 lbs. (139 kg), charge of 120 lbs. (54 kg) TNT and diameter of 29.75 in (75.6 cm).

Similar to the Vickers Elia mines but manufactured by the Royal Navy. Total weight of 448 lbs. (203 kg), charge of 220 lbs. (100 kg) TNT and diameter of 32.9 in (83.6 cm).

First in a series of submarine-laid non-bouyant moored contact mines, this one was designed for 18" (45 cm) torpedo tubes and used side lever firing gear similar to the Elia mines. Charge of 125 lbs. (57 kg) TNT.

Hertz horn mine for 21 in (53 cm) torpedo tubes. This was the first British Hertz mine. Submarines E34, E45, E46 and E51 were modified to carry them. Total weight of 540 lbs. (245 kg), charge of 210 lbs. (95 kg) amatol. Actual size was 78 x 20.85 in (228.6 x 53 cm) including sinker.

As it was felt that the 21 in (53 cm) size did not make a good mine, the S Mark 5 was significantly larger at 31 in (79 cm) and eight submarines of the L class were to be fitted to carry 18 of them. Finished too late to be used during World War I and became the standard submarine-laid mine of the post-war era. Charge of 250 lbs. (113 kg) amatol.

Drifting oscillating mine. Total weight of about 750 lbs. (340 kg) with a charge of 250 lbs. (113 kg) guncotton. These mines were very difficult to maintain with the minelayer HMS Abdiel reporting that only one in ten could be kept in service. Although much experimentation and work was done on this design, it does not appear to have actually entered service use. All Leon mines were ordered scrapped in 1917.

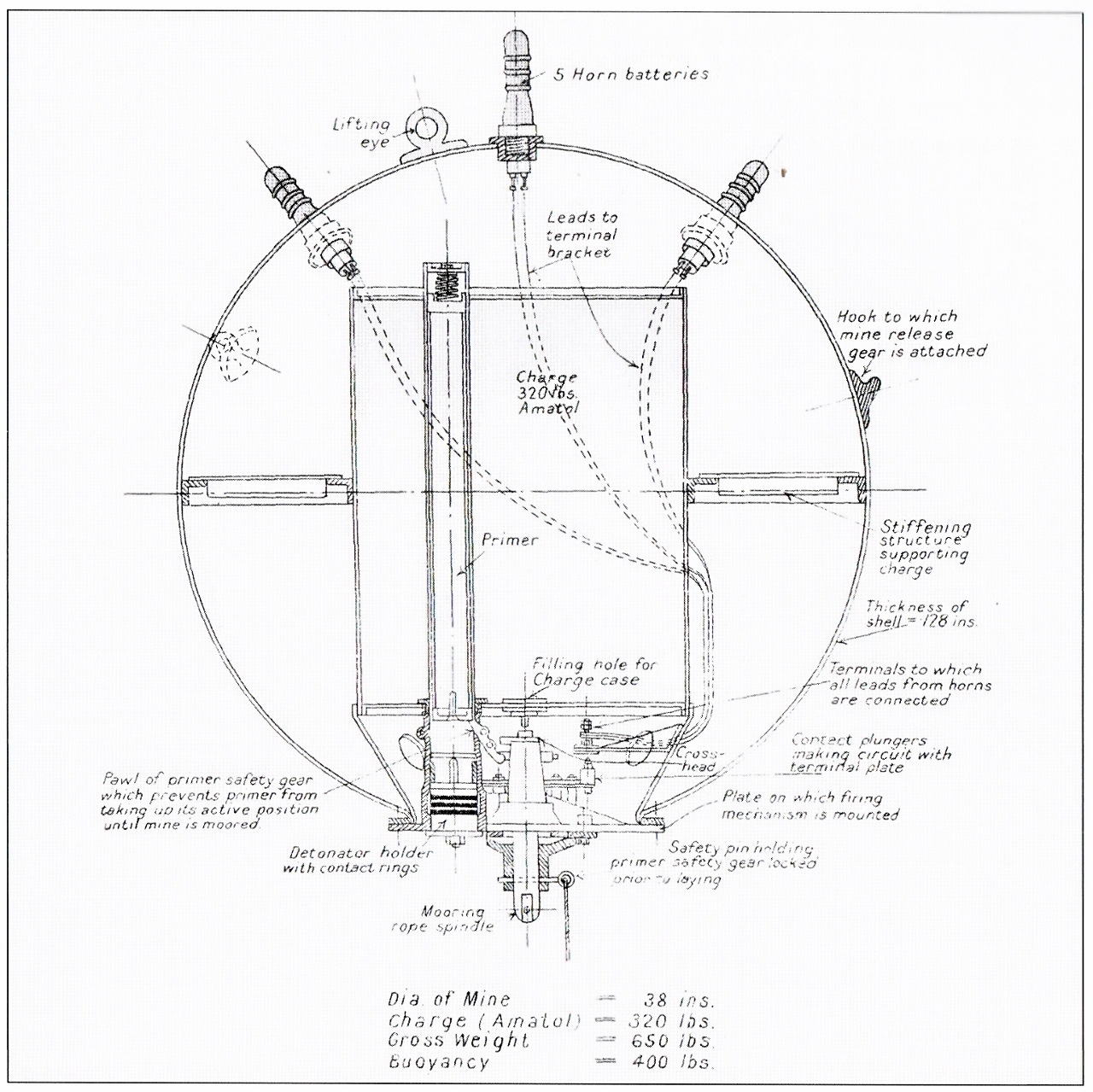

The first reliable British contact-type mine, this was copied from the successful German Hertz-horn contact mine. Production started in early 1917, but it was not available in useful numbers until November 1917. Spherical design. Total weight 650 lbs. (295 kg), charge of 320 lbs. (145 kg) amatol, diameter 38 in (96.5 cm) and used five Hertz horns. Still in use during the early years of World War II.

See 5163 and 5164 at The Vickers Photographic Archive.

Moored contact mine for special operations. Total weight of 100 lbs. (45 kg), charge of 40 lbs. (18 kg) amatol, diameter 22 in (56 cm) and used four Hertz horns.

Another Hertz-horn, spherical design. Total weight of 400 lbs. (181 kg), charge of 150 lbs. (68 kg) amatol, diameter 31 in (79 cm) and used four Hertz horns on top plus two bottom horns pointing upwards.

Another Hertz-horn, spherical design. Total weight of 880 lbs. (399 kg), charge of 500 lbs. (227 kg) amatol, diameter 40 in (102 cm) and used Hertz horns.

Shaped something like an artillery shell, does not appear to have entered service use. Total weight of 120 lbs. (54 kg), charge of 60 lbs. (27 kg) amatol, diameter 13.5 in (34 cm), length approximately 40 in (102 cm) and used Hertz horns.

Britain developed a series of Hertz (acid) horned contact mines just after World War I, with Vickers being heavily involved in production both for the Royal Navy and for other nations. These appear to have been improved versions of the Type H Mark II. I lack data on most of these early designs, but there are many pictures of them and their components; see Submarine Mine at The Vickers Photographic Archive.

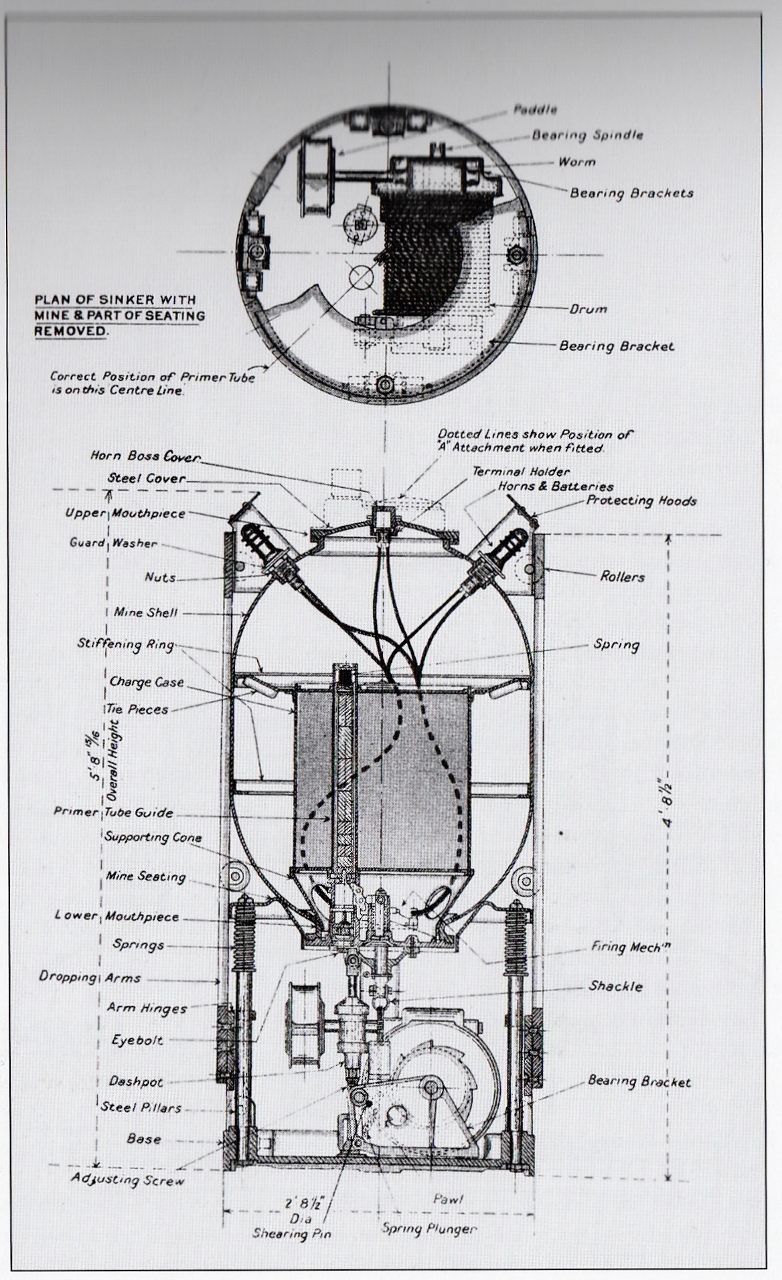

Of special interest in these photographs are the "sinkers" attached to the contact mines. These are the "boxes" that the mines sit in. When deployed from the mine laying craft, the mine and its sinker fall to the bottom of the sea, where upon the mine, connected to the sinker by a tether, is released to float to the top. The sinker then acts as an anchor, retaining the mine in the desired location.

Moored contact mine. Constructed from two hemispheres with a belt between them. Charge weight was 440 lbs. (200 kg) with a 500 foot (150 m) mooring wire. Designed to be placed in waters up to 150 feet (45 m) deep.

A 1920s design with either a 320 lbs. (145 kg) or 500 lbs. (227 kg) charge and Hertz horns. When switch horns were developed this mine became the Mark XVII.

Moored contact mine. Constructed from two 40 inch (102 cm) hemispheres with a 13.5 inch (34 cm) belt between. There were 11 switch horns. Buoyancy 840 lbs. (381 kg) with a 320 lbs. (145 kg) charge and 650 lbs. (295 kg) with a 500 lbs. (227 kg) charge. Originally designed for 200-1000 fathoms (365-1830 m) but its high buoyancy made it valuable in tidal currents and it became a general purpose mine. In 1949, 1,972 were in storage. Redesignated as "Mark 15" in the 1950s.

Similar to the Mark XV except that the shell was thicker. Designed for laying in 100 fathoms (180 m) or less. Hertz horns were used with a 320 lbs. (145 kg) explosive charge.

Similar to the Mark XIV but with a larger belt. Used 11 switch horns and could be laid in waters up to 500 fathoms (915 m) deep. Available charges were 320 lbs. (145 kg), 450 lbs. (204 kg) or 500 lbs. (227 kg). This was the standard British contact mine of World War II. In 1949, 14,933 were in storage.

A small spherical mine with eight switch horns and a 100 lbs. (45 kg) charge. Could be laid in 200 fathoms (360 m) and was intended for anti-submarine barrages at 35 feet (10.7 m) below the surface. The parts were mainly used to build up Mark XIXS and Mark XXVII mines and the rest scrapped in 1944. The Mark XIXS was designed to be used against shallow draft ships.

Moored acoustic mine for use against S and R-boats. Laid in 7-40 fathoms (13-73 m). The charge was 320 lbs. (145 kg) originally and later upped to 500 lbs. (227 kg) in some. In 1949, 14,933 were in storage. Redesignated as "Mark 17" in the 1950s.

Moored antenna mine similar in appearance to the Mark XVII with either a 320 lbs. (145 kg) or 500 lbs. (227 kg) charge. The upper antenna was 60 feet (18 m) and the lower antenna was 74 feet (22.5 m) long. Mark XX* used only the lower antenna.

Similar to Mark XX but had a floating 60 foot (18 m) tubular antenna instead of solid ones supported with floats. Used with either a 320 lbs. (145 kg) or 500 lbs. (227 kg) charge.

A snagline mine intended to be used against S-boats. 40 inches (102 cm) in diameter and very similar to Mark XII*. There were four switch horns, one of which had codline and bottle corks attached. 500 lbs. (227 kg) charge and the mine was laid 15 feet (4.6 m) below the low water mark. Approved in 1943 but replaced by the Mark XVII snagline version shortly after the war.

Submarine mine based upon USN designs. Very little effort was spent developing a production version until January 1945 and did not reach trial stage until late in 1945. Originally intended for magnetic triggers but used an acoustic trigger instead. Total weight was about 3,400 lbs. (1,540 kg) with a warhead of 830 to 850 lbs. (376 to 385 kg).

Submarine launched ground mine. Two of these would occupy the space of one torpedo. Used a CR magnetic trigger and weighed 1,760 lbs. (798 kg) with a 1,000 lbs. (454 kg) minol charge. Could be laid at 8 knots in 5-60 fathoms (9-110 m) and was carried by "T" and a few "S" class submarines. A modification designated Mark IID could be carried by Dutch submarines. A contract for 2,000 was placed in 1940 but production was halted in November 1942. In 1949, 1,310 were in storage.

A CR magnetic mine with a 1,500 lbs. (680 kg) minol charge. Designed for laying from wide-track mine-layer rails in 6-20 fathoms (11-37 m). First deliveries in 1941. Modified in 1942 to increase the charge to 1,600 lbs. (726 kg) amatol or 1,750 lbs. (794 kg) minol. Acoustic triggers added in 1943.

Designed in early 1942 for "A" class submarines. Had increased magnetic sensitivity and acoustic firing. Weight was about 1,880 lbs. (853 kg) with about a 1,110 lbs. (499 kg) minor charge. Production was stopped in November 1942 but resumed in September 1945. Post-war, further development led to a 1,930 lbs. (875 kg) mine with a 1,030 lbs. (467 kg) charge with magnetic, acoustic or combinational fuzing which could be laid by submarines or coastal forces in 6.5 to 20 fathoms. Redesignated as "Mark 5" in the 1950s.

Originally designed to fit the same dropping gear as the 18 inch (45 cm) Mark XI torpedo. First used magnetic only triggering but later versions incorporated acoustic, acoustic-magnetic and magnetic-pressure triggering, although the last one was not used in service. Weight was about 1,500 lbs. (680 kg) with a 750 lbs. (340 kg) charge.

Similar to Mark I but with less use of scarce material. Some were fitted for impact firing. Mark III*** was for dropping from Mosquitoes at 260 knots from 300 feet (90 m) into inland waterways. Designed to be dropped from 4,000 lbs. (1,814 kg) bomb gear.

A parachute mine with magnetic firing dropped from 1,000 lbs. (454 kg) bomb racks. Production started in August 1940. Weight 1,080 lbs. (490 kg) with a 700 lbs. (318 kg) minol charge.

Production started in 1944 for this parachute mine intended to replace A Marks I-IV. Used an acoustic-magnetic trigger and was the dimensions of a 2,000 lbs. (907 kg) blast bomb. Charge was 1,000 lbs. (454 kg) amatol or 1,100 lbs. (499 kg) minol. Without parachute could also be laid by MTBs or from low altitude. In 1949, some 5,707 were in storage.

An improved version of the A Mark VI introduced in 1944. Had only magnetic triggering as originally deployed, but acoustic sensors were added sometime later, possibly post-war. Weight of 1,100 lbs. (499 kg) with a 555 or 610 lbs. (252 or 277 kg) charge. Minimum case depth was 40 feet (12 m). Dimensions were 18.5 in x 7.5 feet (47 cm x 2.3 m) or 6.9 feet (2.1 m) without parachute. In 1949, 4,502 were in storage. Redesignated as "Mark 7" in the 1950s.

A small magnetic mine for rivers and designed to fit 500 lbs. (227 kg) GP bomb gear. An acoustic version, A Mark VIII* was apparently not used during the war. Weight of 500 lbs. (227 kg) with a 180 lbs. (82 kg) amatol or 200 lbs. (91 kg) minol charge.

Similar to A Mark VI but designed to fit newer aircraft. Could use a pressure trigger as well as magnetic. Post-war modifications added acoustic sensors. Weight 1,775-1,845 lbs. (805-837 kg) with a 1,045 (474 kg) minol charge. Minimum case depth was 40 feet (12 m). Dimensions were 18.5 in x 9.33 feet (47 cm x 2.8 m) or 8.5 feet (2.6 m) without parachute. In 1949, 1,427 were in storage and 400 were on order.

A moored mine designed to fit 1,000 lbs. (454 kg) GP bomb gear. Had a very small charge of 100 lbs. (45 kg). Used inertia switches for firing and could be laid in 10-40 fathoms (18-73 m). There was little use for this mine and it was not in service.

Developed in 1953-56 as air-launched ASW ground mine. Weight 1,000 lbs. (454 kg). Used combination acoustic-magnetic-pressure triggers. At the time of development, the standard air-drop requirements were 450 knots/5,000 feet (1,500 m) and 12 foot (3.7 m) depth for RN aircraft and 35,000 feet (10,700 m) and 40 foot (12 m) depth for RAF aircraft.

Air-launched ASW ground mine developed in 1953-56 as a heavier companion to the A Type S. Weight 2,000 lbs. (908 kg). Used combination acoustic-magnetic-pressure triggers. At the time of development, the standard air-drop requirements were 450 knots/5,000 feet (1,500 m) and 12 foot (3.7 m) depth for RN aircraft and 35,000 feet (10,700 m) and 40 foot (12 m) depth for RAF aircraft. Redesignated as "Mark 12" in the 1950s.

Aircraft laid buoyant mine. Used a contact trigger and the cable length had to be adjusted before flight. This mine was intended to be as simple and inexpensive as possible and was the only weapon capable of being used in waters not accessible to submarines and surface ships. Weight of 810 lbs. (367 kg) with a 100 lbs. (45 kg) minol charge.

Small anti-invasion mine of about 187 lbs. (85 kg) intended for use in shallow waters of 100 feet (30 m) or less. The technology is similar to that in the Marconi Stonefish, which is intended to be used in deeper waters. Uses two types of influence (magnetic) sensors and has a 200 day operational lifetime. Produced only for export.

Uses a combination acoustic/magnetic/pressure trigger and replaces earlier British mines. Can be launched by plane, ship or submarine for use in depths of 100-660 feet (30-200 m). Weight of 2,180 lbs. (990 kg) with a 1,320 lbs. (600 kg) Torpex warhead. Shelf life is 20 years with a 700 day operational lifetime. The Mark 2 is shorter and lighter with a 1,100 lbs. (500 kg) charge of PBX and a much simpler firing circuit (over 30 components were eliminated). Never purchased by the Royal Navy, this mine has only been produced for export.

As of the early 1990s, only the Mark 5, Mark 12 and Mark 17 were in service use.

The Mark 17 appears to have been withdrawn from service sometime in the mid to late 1990s.

Britain has not manufactured mines for some years, probably since the 1950s. In 1982, a modernization program was announced for about 1,500 mines, some of them dating back to World War II. In 1984 it was reported that the entire program might have to be abandoned as inspection showed that the TNT or RDF fillings had crystallized, causing at least two mines to explode prematurely. The solution was to X-ray each mine and discard those that showed cracks or crystallization. As of 1994, only Mark 12 mines had been modernized, mainly by adding the British Aerospace microprocessor sensor and processing unit (SAP) described above.

"Naval Weapons of World War Two" by John Campbell

"America's Use of Sea Mines" by Robert C. Duncan, Ph.D.

"US Naval Weapons", "The Naval Institute Guide to World Naval Weapon Systems 1991/92", "The Naval Institute Guide to World

Naval Weapon Systems 1994 Update" and "Naval Weapons of World War One" all by Norman Friedman

"Depth Charge: Royan Naval Mines, Depth Charges & Underwater Weapons 1914 - 1945" by Chris Henry

"Find and Destroy: Antisubmarine Warfare in World War I" by Dwight R. Messimer

10 August 2008 - Benchmark

17 January 2009 - Added photograph of spherical minelayer

28 December 2013 - Added photograph of HMS Apollo

18 June 2014 - Added photograph of HMS Aurora

28 November 2015 - Changed Vickers Photographic Archive links to point at Wayback Archive

14 February 2018 - Converted to HTML 5 format

01 August 2019 - Added information on World War I mines